ABOUT US

GAURAV INDUSTRIES is a leading precision machining component manufacturing company, specializing in the design and production of high-precision components for various industries. With a strong commitment to quality, innovation, and customer satisfaction, we deliver tailored solutions that meet the exacting standards of our clients.

Our state-of-the-art manufacturing facility coupled with cutting edge technical expertise offers high quality products and cost-effective solutions that match global standards as well as customer requirements.

Glimpse Of Our Facility

- Vertical Milling Center (VMC) Machines, CNC Machines, Polygon Machines, Broaching –Machines and many more.

- Quality Control: CMM (ZEISS), Contour Measuring Machines (ZEISS), 2D Height Gauge –

(EMS) and many more. - ISO 9001:2015 certified company.

- We are working on this certification:

ISO 14001:2015 Environmental management system

ISO 45001:2018 Occupational health and safety management system

IATF 16949:2016 - Facility total area is 26000 sq. feet.

- Facility built-up are is 16000 sq. feet.

- 10000 sq. feet is spare area for future expansion.

- In-House tooling and fixture development facility for rapid development activity.

Facility Overview

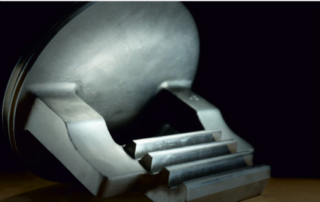

Machining

Capability

CONVENTIONAL FULL SETUP

FULL SETUP OF CONVENTIONAL MACHINE DRILL ,LETH, SHEPING,MILING,

MICRON MACHINE

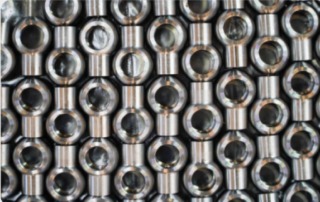

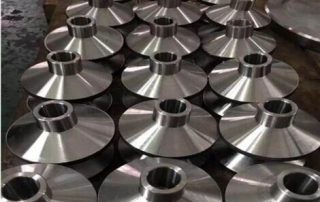

Our Products

Our state-of-the-art manufacturing facility coupled with cutting edge technical expertise offers high quality products and cost-effective solutions that match global standards as well as customer requirements

Quality Controls Facility Overview

Being as an ISO 9001:2015 approved organization, we achieve high quality standards through in-house measuring systems with a well-equipped Standards Room that includes:

- Co-ordinate Measuring Machine (CMM) with 0.1 Micron Resolution – (ZEISS)

- Contour Measuring Machine – (ZEISS) & 2D height gauge – (EMS)

- Digi Profile Projector 400E with 1 Micron Linear and 1 second rotational Resolution – Mitutoyo.

- Roughness tester, hardness tester, Spectro analysis, and high precision gauges.

Measuring Equipments

- Vernier Callipers – Up to 900 mm

- Digital height gauge upto 600mm

- Micrometer – Upto to 400 mm

- Slip Gauge Box ‘0’ Grade 2 Boxes Consisting Of 122 Pcs

- Lever & Plunger Type Dial Indicators With Stand 10 mm

- Thread plug gauges, Thread ring gauges, Plug Gauges, Snap Gauges etc.

- Surface Plate

- Bench Center

- Coating Thickness Measuring Equipment

- Surface Roughness Tester

Testing Facilities

- Salt Spray Tests

- Vibration Testing & Load Tests like Static, Radial , Axial

- Raw Material Testing

- Radiographic Testing (RT)

- Chemical Composition & Physical Properties

- Charpy Impact Test

- Magnetic Particle Inspection

- Ultrasound Testing

- Microstructure Analysis

Material Flow & Process Control

Industries We Serve

Valve

Pump

Automobile

Automation

General

Engineering

Oil Field

Equipment

Food & Pharma

Agriculture

Equipments

Earth Moving

Equipments

Power

Plants

Process & Material Experience

Special Process

Surface Treatments

Material Treatments

Materials we are dealing with

All types of Casting, Forging and Round Bars Grades in Ferrous and Non-Ferrous material

Our expertise

in complex geometrical machining

Our Group of Companies

Every Thing is Here

CONTACT US

Gaurav Industries

Ready to discuss your project or have questions about our services? Contact Gaurav Industries today.

We are servicing worldwide:

Asia Pacific

India

Thailand

Malaysia

Europe, Middle East

Poland

Italy

France

Switzerland

Germany

Sweden

Denmark

Spain

Israel

North America

USA

Managing Director:

Mr. Bharat Kapadiya

+91 97251 39678

bharat.k@gaurav-industries.com